STRAIN GAUGE ANCHOR LOAD CELLS SGLC-7000

The SGLC 7000 series load cell consists of a cylinder of high strength steel with a series of electrical resistance strain gauges connected around the periphery as a Wheatstone Bridge that compensates for unevenly distributed loads and provides a single mV/V signal output.

They are manufactured with a center hole to accommodate anchors, rock bolts and tendons.

Categories: Geo-Structural Instruments, Load Cells

Description

When the load cell is subjected to load the resistance of the strain gauges will change and the output signal is directly proportional to the applied load. The load cells are compensated for temperature variations often found during normal operating environments and have in-built lightning protection.

Connection to the load cell is via a heavy duty multi-core sheathed cable which can be connected to a direct portable readout, switched terminal units or a data logging system. Mounting surfaces should be flat and parallel for optimum performance and the use of bearing plates and load distribution plates is recommended.

The bearing plate (provided locally) is normally made to suit specific site requirements and the load distribution plate (supplied by Geosense) should be inserted between the load cell and the anchor head.

Additional information

| Brands | |

|---|---|

| Range |

300 to 2500kN |

| Bridge Resistance |

1400Ω |

| Over Range |

up to 130% |

| Sensitivity |

2.0 mV/V +/-0.15% |

| Accuracy |

< ±0.3% FS |

| Temperature Compensation |

-10°C / +60°C |

| Output Signal |

1.5 mV/V |

| Power Input |

5 to 15 V DC |

| Operating Temperature |

-20ºC to + 70ºC |

Reviews (0)

Be the first to review “STRAIN GAUGE ANCHOR LOAD CELLS SGLC-7000” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

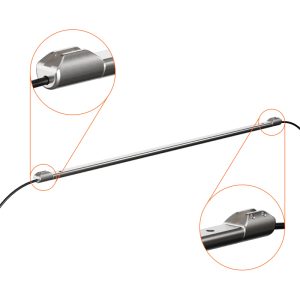

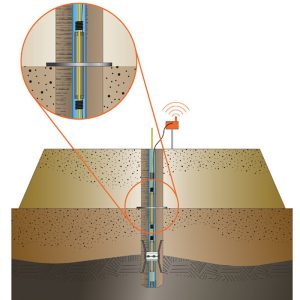

IPX IN-PLACE EXTENSOMETER

In stock

Rated 0 out of 5

The In-Place Extensometer (IPX) offers automated monitoring of standard magnetic extensometer installations. The system is designed for a simple, adaptable installation with a single cable connection at the top of the borehole. Its large measurement range accommodates large levels of settlement or heave, and ease of adjustment means it can be reconfigured for changed site conditions such as embankment filling or cutting.

DRIVE-IN PIEZOMETERS WP-3400 & SGP-3500 SERIES

In stock

Rated 0 out of 5

Drive-in piezometers, also referred to as push-in piezometers, are designed for installing in soft clays, organic or fine grained cohesionless soils typically with a SPT-N value less than 10. They are available with a CPT fitting or 1” BSP thread.

Depending on the depth and type of soil, they can either be pushed directly into the soil from ground level to the required depth or pushed into the base of a CPT test or drilled borehole.

PRESSURE TRANSDUCER VWT-9000 SERIES

In stock

Rated 0 out of 5

The Geosense® VWT-9000 Series of Pressure Transducers are designed to be connected directly into hydraulic or pneumatic pressure lines by means of a 1/4” BSPF thread. Other thread sizes are available on request.

They are typically used to monitor uplift pressures within dams and to enable manual standpipe piezometers to be upgraded into an automated data acquisition system.

OPTICAL DISPLACEMENT SENSOR NODE

In stock

Rated 0 out of 5

SUBMERSIBLE TILT METER

In stock

Rated 0 out of 5

IN-PLACE INCLINOMETER (IPI)

In stock

Rated 0 out of 5

DIGITAL PIEZOMETER – dPiezo

In stock

Rated 0 out of 5

IMAGING & CAMERA

In stock

Rated 0 out of 5

The FlatMesh 4G Camera is a best in class solar powered solution for static imagery in remote or industrial areas.

It contains a monochrome digital camera which can take clear, high quality photographs day or night without the use of external illuminators.

The 4G camera connects to a Senceive EdgeHub (with FlatMesh) unit which provides power and connectivity over the cellular network (2G/3G/4G) or existing wired ethernet networks.

Reviews

There are no reviews yet.