INCLINOMETER CASING XC

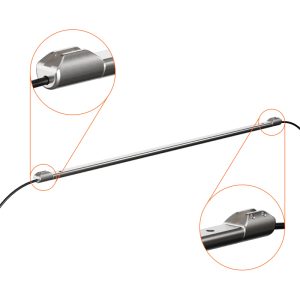

Geosense® XC (External Coupler) Inclinometer Casing is a precision extruded from ABS, with four precise keyways formed at 90 degrees which allow accurate installation of portable and in-place inclinometers.

Categories: Geo-Structural Instruments, Inclinometers

Description

Standard joints are made by using external couplers which are glued to each end of the casing. Telescopic sections are riveted together to allow movement during settlement and sealed with mastic and tape to prevent the ingress of water and grout.

Advantages of the XC Inclinometer casing is that it can be cut and re-joined on site allowing maximum flexibility and makes any damage easily repairable.

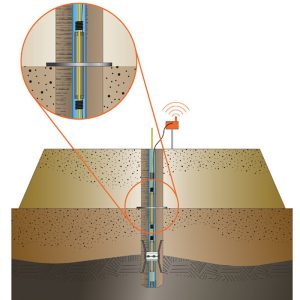

It can be used in boreholes, fill material, cast into concrete or attached to structures and is designed to move with the ground, material or structure to provide inclination information over a period of time.

As the casing is designed to deform with movement of the ground or structure the useful life of the casing ends when the continued movement of the casing causes deformation of shear so that the inclinometer probe can no longer be placed into the casing. Larger casing generally ensures a longer life.

Where vertical settlement or heave is anticipated to be greater than 2% it is recommended to use telescopic sections to eliminate axial load on the casing which would cause buckling.

A full range of accessories including bottom and top caps, anchors and groutable anchors are available and can be used in conjunction with magnetic targets for combined inclinometer/magnetic extensometers.

Additional information

| Brands | |

|---|---|

| Dimensions |

70 & 87 mm |

| Material |

ABS (Acrylonitrile-butadiene-styrene) |

| Groove spiral |

< 0.3°/3m |

| Joint strength |

710 Kgf |

| Maximum Temperature |

+80°C |

| Colour |

Natural (other available on request) |

Reviews (0)

Be the first to review “INCLINOMETER CASING XC” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

IPX IN-PLACE EXTENSOMETER

In stock

Rated 0 out of 5

The In-Place Extensometer (IPX) offers automated monitoring of standard magnetic extensometer installations. The system is designed for a simple, adaptable installation with a single cable connection at the top of the borehole. Its large measurement range accommodates large levels of settlement or heave, and ease of adjustment means it can be reconfigured for changed site conditions such as embankment filling or cutting.

DRIVE-IN PIEZOMETERS WP-3400 & SGP-3500 SERIES

In stock

Rated 0 out of 5

Drive-in piezometers, also referred to as push-in piezometers, are designed for installing in soft clays, organic or fine grained cohesionless soils typically with a SPT-N value less than 10. They are available with a CPT fitting or 1” BSP thread.

Depending on the depth and type of soil, they can either be pushed directly into the soil from ground level to the required depth or pushed into the base of a CPT test or drilled borehole.

NANO TRIAXIAL TILT SENSOR

In stock

Rated 0 out of 5

The Nano range uses the same core platform as our other tilt sensors, so it can deliver a similar level of performance and reliability, all in a small and robust enclosure. Nanos have been successfully used in many applications, including:

- Tunnel distortion

- Tunnel heave/settlement

- Embankment slippage (used in conjunction with stake mounts)

- Structural movement

- Rail track heave/settlement

- Rail trackbed cant and twist

TRIAXIAL TILT SENSOR NODE

In stock

Rated 0 out of 5

STANDPIPE PIEZOMETER

In stock

Rated 0 out of 5

PENDULUM SYSTEM

In stock

Rated 0 out of 5

HPS-3500 (Hanging) and IPS-3000 (Inverted) Pendulums are used to measure the tilt or rotation by measuring the relative internal horizontal displacement of points along a true vertical line. Each has a tensioned, stainless steel wire and the effects of the earth gravitational forces to guarantee a perfectly vertical line between a fixed point and a tensioning mechanism. Typical applications include concrete dams, bridges and high rise buildings.

INCLINOMETER CASING QJ

In stock

Rated 0 out of 5

MAGNETIC EXTENSOMETER GXM RANGE

In stock

Rated 0 out of 5

The GEO-XM settlement system is a magnet extensometer system used typically to monitor settlement and heave in foundations, excavations and embankments.

Data received identifies the depth and position where settlement has occurred as well as the total amount of settlement.

It can also be installed behind retaining structures, such as sheet piles and slurry walls, and above underground openings, such as tunnels and shafts.

Reviews

There are no reviews yet.