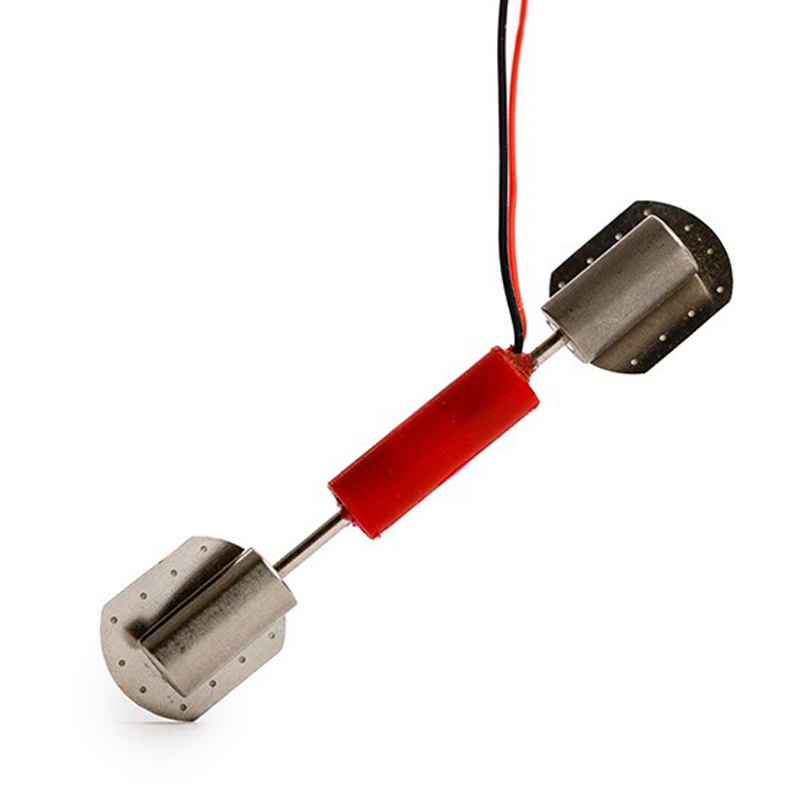

VW STRAIN GAUGE SPOT WELD VWS-2020

The VWS-2020 series vibrating wire strain gauges are designed primarily to measure strains on the surface of steel structures but may also be used on other types of material.

The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks are attached to stainless steel tabs which may be attached to steel structures by spot welding or, using alternative end blocks, bonded or grouted.

Precision tensioning is carried out on site using a special tensioning jig and the gauge can be set for compression, tension or at mid-point.

Categories: Geo-Structural Instruments, Strain Gauges

Description

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

Around the wire is a magnetic coil which when pulsed by a vibrating wire readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

As the steel or other surface undergoes strain the end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

VWS-2020 strain gauges are available in two versions:

- Gauge with integral coil housing

- Gauge only with separate coil housing

Additional information

| Brands | |

|---|---|

| Strain Range |

3000 με |

| Resolution |

0.4 με |

| Accuracy |

±0.1% (individual calibration) to ±0.5% (standard batch calibration) FS |

| Non linearity |

<0.5% FS |

| Temperature range |

-20°C to +80°C |

| Gauge length |

49 mm |

| Overall length |

65 mm |

Reviews (0)

Be the first to review “VW STRAIN GAUGE SPOT WELD VWS-2020” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

VW PIEZOMETER VWP-3000 SERIES

In stock

Rated 0 out of 5

DRIVE-IN PIEZOMETERS WP-3400 & SGP-3500 SERIES

In stock

Rated 0 out of 5

Drive-in piezometers, also referred to as push-in piezometers, are designed for installing in soft clays, organic or fine grained cohesionless soils typically with a SPT-N value less than 10. They are available with a CPT fitting or 1” BSP thread.

Depending on the depth and type of soil, they can either be pushed directly into the soil from ground level to the required depth or pushed into the base of a CPT test or drilled borehole.

OPTICAL DISPLACEMENT SENSOR NODE

In stock

Rated 0 out of 5

NANO TRIAXIAL TILT SENSOR

In stock

Rated 0 out of 5

The Nano range uses the same core platform as our other tilt sensors, so it can deliver a similar level of performance and reliability, all in a small and robust enclosure. Nanos have been successfully used in many applications, including:

- Tunnel distortion

- Tunnel heave/settlement

- Embankment slippage (used in conjunction with stake mounts)

- Structural movement

- Rail track heave/settlement

- Rail trackbed cant and twist

PENDULUM SYSTEM

In stock

Rated 0 out of 5

HPS-3500 (Hanging) and IPS-3000 (Inverted) Pendulums are used to measure the tilt or rotation by measuring the relative internal horizontal displacement of points along a true vertical line. Each has a tensioned, stainless steel wire and the effects of the earth gravitational forces to guarantee a perfectly vertical line between a fixed point and a tensioning mechanism. Typical applications include concrete dams, bridges and high rise buildings.

INCLINOMETER CASING QJ

In stock

Rated 0 out of 5

IMAGING & CAMERA

In stock

Rated 0 out of 5

The FlatMesh 4G Camera is a best in class solar powered solution for static imagery in remote or industrial areas.

It contains a monochrome digital camera which can take clear, high quality photographs day or night without the use of external illuminators.

The 4G camera connects to a Senceive EdgeHub (with FlatMesh) unit which provides power and connectivity over the cellular network (2G/3G/4G) or existing wired ethernet networks.

INCLINOMETER CASING XC

In stock

Rated 0 out of 5

Reviews

There are no reviews yet.