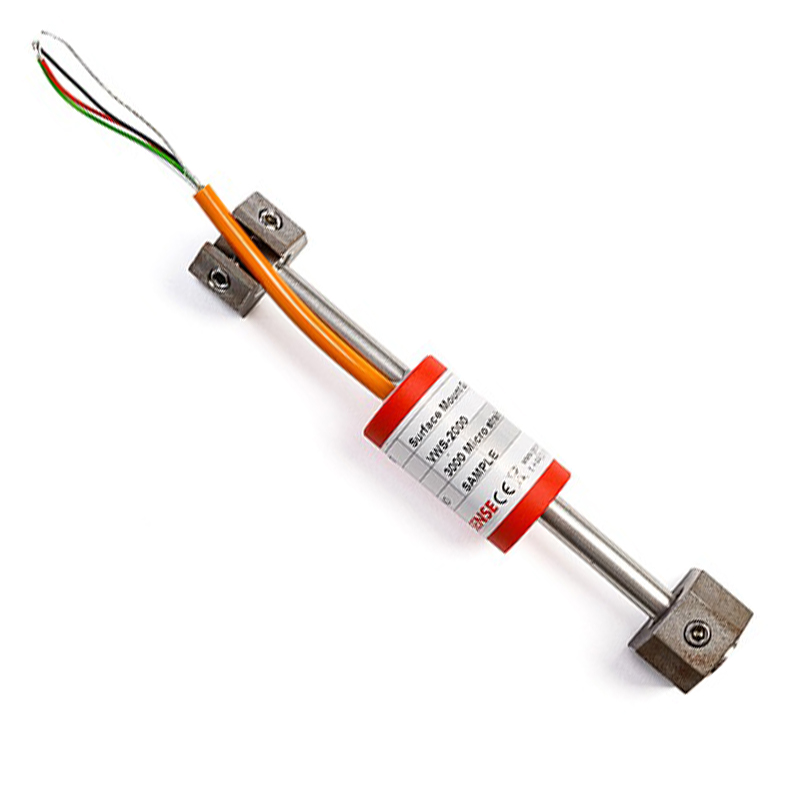

VW STRAIN GAUGE SURFACE MOUNT VWS-2000

The VWS-2000 series vibrating wire surface strain mount gauges are designed for the long term monitoring of steel or concrete structures. Gauges may be attached to steel structures by arc welding or, using alternative end blocks, bonded or grouted into concrete.

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

Categories: Geo-Structural Instruments, Strain Gauges

Description

The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks can be attached by either arc welding, bonding or groutable anchors to steel or concrete.

Around the wire is a magnetic coil which when pulsed by a vibrating readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

As the steel or concrete surface undergoes strain the end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

Additional information

| Brands | |

|---|---|

| Strain Range |

3000 με |

| Gauge length |

VWS-2000: 150mm; VWS-2010: 89mm |

| Overall length |

VWS-2000: 156mm; VWS-2010: 95mm |

| Resolution |

1 με |

| Accuracy |

±0.1 (individual calibration) to ±0.5% FS (standard batch calibration) |

| Non linearity |

<0.5% FS |

| Temperature |

-20°C to +80°C |

| Frequency range |

VWS-2000: 850-1550 VWS-2010: 900-2000 |

Reviews (0)

Be the first to review “VW STRAIN GAUGE SURFACE MOUNT VWS-2000” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

VW PIEZOMETER VWP-3000 SERIES

In stock

Rated 0 out of 5

VWPHT-3600 SERIES

In stock

Rated 0 out of 5

The VWPHT-3600 series High Temperature Piezometers are suitable for the extreme environments of temperature and pressure found within applications such as geothermal heat and enhanced oil recovery systems including steam assisted gravity drainage (SAGD) and cyclic steam stimulation (CSS). They are capable of monitoring high temperatures up to 250°C and pressures up to 34.5 MPa.

SUBMERSIBLE TILT METER

In stock

Rated 0 out of 5

DIGITAL PIEZOMETER – dPiezo

In stock

Rated 0 out of 5

TILT BEAM MEMS

In stock

Rated 0 out of 5

MEMS Tilt Beams are designed for attachment to structures, on either a vertical or horizontal surface, for the measurement of tilt or differential settlement.

They consist of a highly accurate MEMS sensor housed in a fully sealed enclosure which is mounted on a lightweight rigid GRP beam. This can be mounted onto the structure using special anchors. The GRP beam has a very low coefficient of thermal expansion meaning that thermal affects are minimised.

INCLINOMETER CASING XC

In stock

Rated 0 out of 5

INCLINOMETER SPIRAL SENSOR

In stock

Rated 0 out of 5

MAGNETIC EXTENSOMETER GXM RANGE

In stock

Rated 0 out of 5

The GEO-XM settlement system is a magnet extensometer system used typically to monitor settlement and heave in foundations, excavations and embankments.

Data received identifies the depth and position where settlement has occurred as well as the total amount of settlement.

It can also be installed behind retaining structures, such as sheet piles and slurry walls, and above underground openings, such as tunnels and shafts.

Reviews

There are no reviews yet.