MULTI-POINT VW PIEZOMETER

Fully grouted installation permits multiple piezometers to be simply and reliably installed in a single borehole. The piezometer string and grout pipe are placed in the borehole and cement-bentonite grout is pumped until the borehole is filled.

Categories: Geo-Structural Instruments, Piezometers

Description

Multi-point Piezometer Strings allow for multiple Vibrating Wire Piezometers to be connected on a single cable. This facilitates the installation of fully grouted multiple piezometers. The single cable prevents vertical void channels. Tough urethane jacketed, Kevlar® reinforced, non-stretch cable is employed to withstand the rigours of installation and is entirely water-blocked to minimize any leakage. No conductors are shared to maximize independent reliability of each sensor.

Vibrating Wire Piezometers provide excellent long-term accuracy, stability of readings and reliability under demanding geotechnical conditions. Vibrating Wire Piezometers are the electrical piezometers of choice as the frequency output of vibrating wire devices is immune to external electrical noise, and able to tolerate wet wiring common in geotechnical applications.

Additional information

| Brands | |

|---|---|

| Over range |

1.5 x FS |

| Resolution |

0.025% F.S. minimum |

| Accuracy |

0.1% FS |

| Operating Temperature |

-20 to +70°C |

| Materials |

316 stainless steel |

| Pressure range |

345 kPa to 3.5 MPa |

Reviews (0)

Be the first to review “MULTI-POINT VW PIEZOMETER” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

About Brand

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors and a range of inherently safe pneumatic pumps for use in the environmental sector.

Data Sheets

Related products

VW PIEZOMETER VWP-3000 SERIES

In stock

Rated 0 out of 5

BOREHOLE ROD EXTENSOMETER

In stock

Rated 0 out of 5

The Geosense® GEO-XB2 borehole rod type extensometer range is used to measure and locate settlement, displacement and deformation in soil and rock.

It consists of a reference head and one or more in-hole anchors each of which is placed at a known depth and connected to the reference head by either a rigid or flexible rod running inside a flexible sleeve, which keeps the rod de-bonded from the grout.

DRIVE-IN PIEZOMETERS WP-3400 & SGP-3500 SERIES

In stock

Rated 0 out of 5

Drive-in piezometers, also referred to as push-in piezometers, are designed for installing in soft clays, organic or fine grained cohesionless soils typically with a SPT-N value less than 10. They are available with a CPT fitting or 1” BSP thread.

Depending on the depth and type of soil, they can either be pushed directly into the soil from ground level to the required depth or pushed into the base of a CPT test or drilled borehole.

OPTICAL DISPLACEMENT SENSOR NODE

In stock

Rated 0 out of 5

TRIAXIAL TILT SENSOR NODE

In stock

Rated 0 out of 5

IN-PLACE TILT METER MEMS

In stock

Rated 0 out of 5

STANDPIPE PIEZOMETER

In stock

Rated 0 out of 5

IMAGING & CAMERA

In stock

Rated 0 out of 5

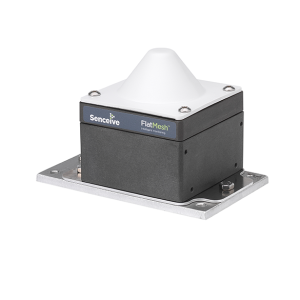

The FlatMesh 4G Camera is a best in class solar powered solution for static imagery in remote or industrial areas.

It contains a monochrome digital camera which can take clear, high quality photographs day or night without the use of external illuminators.

The 4G camera connects to a Senceive EdgeHub (with FlatMesh) unit which provides power and connectivity over the cellular network (2G/3G/4G) or existing wired ethernet networks.

Reviews

There are no reviews yet.