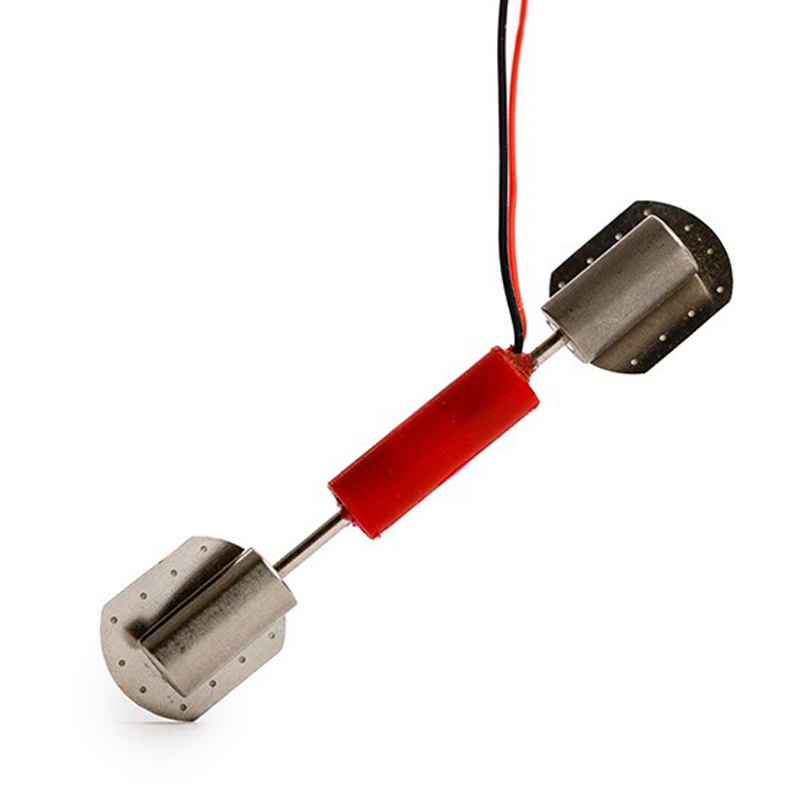

VW STRAIN GAUGE SPOT WELD VWS-2020

The VWS-2020 series vibrating wire strain gauges are designed primarily to measure strains on the surface of steel structures but may also be used on other types of material.

The gauge consists of two end blocks with a tensioned steel wire between them. The end blocks are attached to stainless steel tabs which may be attached to steel structures by spot welding or, using alternative end blocks, bonded or grouted.

Precision tensioning is carried out on site using a special tensioning jig and the gauge can be set for compression, tension or at mid-point.

Categories: Geo-Structural Instruments, Strain Gauges

Description

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

Around the wire is a magnetic coil which when pulsed by a vibrating wire readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

As the steel or other surface undergoes strain the end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

VWS-2020 strain gauges are available in two versions:

- Gauge with integral coil housing

- Gauge only with separate coil housing

Additional information

| Brands | |

|---|---|

| Strain Range |

3000 με |

| Resolution |

0.4 με |

| Accuracy |

±0.1% (individual calibration) to ±0.5% (standard batch calibration) FS |

| Non linearity |

<0.5% FS |

| Temperature range |

-20°C to +80°C |

| Gauge length |

49 mm |

| Overall length |

65 mm |

Reviews (0)

Be the first to review “VW STRAIN GAUGE SPOT WELD VWS-2020” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

BOREHOLE ROD EXTENSOMETER

In stock

Rated 0 out of 5

The Geosense® GEO-XB2 borehole rod type extensometer range is used to measure and locate settlement, displacement and deformation in soil and rock.

It consists of a reference head and one or more in-hole anchors each of which is placed at a known depth and connected to the reference head by either a rigid or flexible rod running inside a flexible sleeve, which keeps the rod de-bonded from the grout.

STRAIN GAUGE PIEZOMETER SGP-3400 SERIES

In stock

Rated 0 out of 5

The SGP-3400 Series of strain gauge piezometers are designed for monitoring soil pore pressure or changes in water level and are also suitable for dynamic monitoring such as pumping tests.

They are accurate, highly-reliable and suitable for use in the harsh environments often found within civil engineering including water wells, boreholes, dams, reservoirs, rivers, tanks or any other body of water.

SUBMERSIBLE TILT METER

In stock

Rated 0 out of 5

PORTABLE MEMS INCLINOMETER

In stock

Rated 0 out of 5

The MEMS Portable Inclinometer system utilises modern communication and Smart devices to enable the tilt data generated by the probe to be managed, stored and transferred directly from site via FTP, API, email or other communication platforms.

It is available for vertical, inclined and horizontal applications.

TILT BEAM

In stock

Rated 0 out of 5

The Tilt Beam is a lightweight, rigid aluminium beam that is used in conjunction with a Triaxial Tilt Node, a NanoPlus or a NanoMacro.

The tilt beam has been successfully used in many applications, including:

- Movement monitoring of any structure

- Longitudinal settlement

- Tunnel convergence/divergence

- Lateral displacements

TILT BEAM MEMS

In stock

Rated 0 out of 5

MEMS Tilt Beams are designed for attachment to structures, on either a vertical or horizontal surface, for the measurement of tilt or differential settlement.

They consist of a highly accurate MEMS sensor housed in a fully sealed enclosure which is mounted on a lightweight rigid GRP beam. This can be mounted onto the structure using special anchors. The GRP beam has a very low coefficient of thermal expansion meaning that thermal affects are minimised.

INCLINOMETER CASING QJ

In stock

Rated 0 out of 5

IMAGING & CAMERA

In stock

Rated 0 out of 5

The FlatMesh 4G Camera is a best in class solar powered solution for static imagery in remote or industrial areas.

It contains a monochrome digital camera which can take clear, high quality photographs day or night without the use of external illuminators.

The 4G camera connects to a Senceive EdgeHub (with FlatMesh) unit which provides power and connectivity over the cellular network (2G/3G/4G) or existing wired ethernet networks.

Reviews

There are no reviews yet.