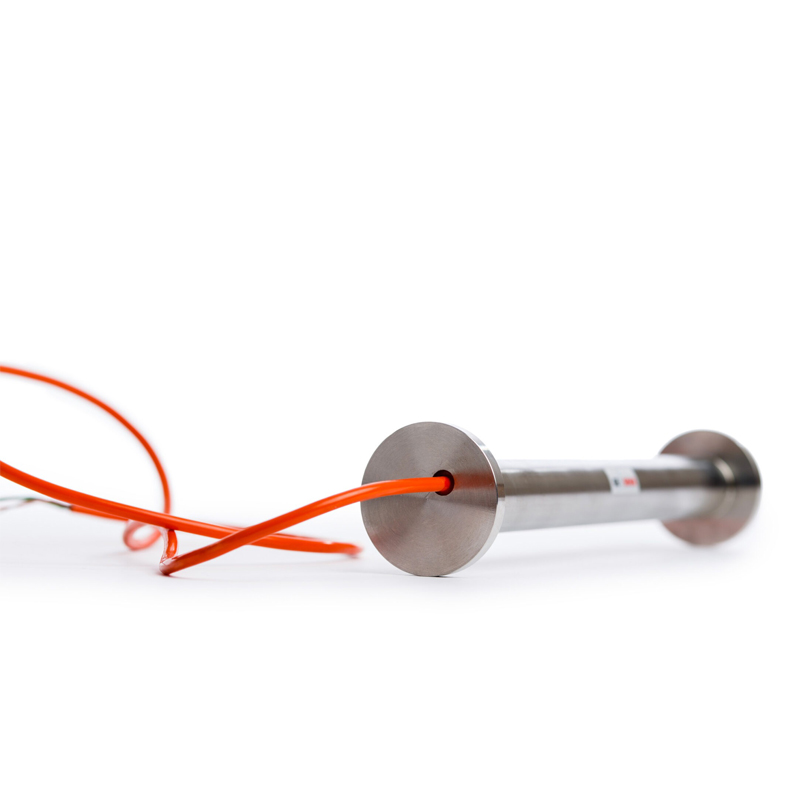

VW STRAIN GAUGE EMBEDMENT VWS-2100

The VWS-2100 series vibrating wire embedment strain gauges are designed for direct embedment in concrete.

The strain gauge operates on the principle that a tensioned wire, when plucked, vibrates at its resonant frequency. The square of this frequency is proportional to the strain in the wire.

The gauge consists of two end blocks with a tensioned steel wire between them. Around the wire is a magnetic coil which when pulsed by a vibrating readout or data logger interface plucks the wire and measures the resultant resonant frequency of vibration.

Categories: Geo-Structural Instruments, Strain Gauges

Description

Deformation within the concrete will cause the two end blocks will move relative to each other. The tension in the wire between the blocks will change accordingly thus altering the resonant frequency of the wire.

VWS-2125 can be used within mass concrete with coarse aggregates as its heavy duty construction resists bending and the large end flanges provide a high contact area.

Additional information

| Brands | |

|---|---|

| Strain range |

3000 με |

| Gauge length |

50mm, 150mm, 250mm |

| Overall length |

54mm, 156mm, 260mm |

| Resolution |

1 με |

| Accuracy |

±0.1% (individual calibration) to ±0.5% (standard batch calibration) FS |

| Non linearity |

<0.5% FS |

| Temperature range |

-20°C to +80°C |

| Frequency range |

850-1550Hz |

Reviews (0)

Be the first to review “VW STRAIN GAUGE EMBEDMENT VWS-2100” Cancel reply

About brand

Geosense Ltd is one of Europe’s leading manufacturers and suppliers of instruments to the geotechnical, civil engineering, mining and environmental industries.

Geosense products are used globally in major projects in more than 68 countries. With a comprehensive in-house design and manufacturing capability, we can provide products not only to tight deadlines but also to suit custom-engineered solutions for specific project requirements.

Geosense specialises in the manufacture of vibrating wire and MEMS sensors, which are used to produce a wide range of instruments. In addition we manufacture automated data acquisition systems to complement our sensors, including wireless systems.

Data Sheets

Related products

MULTI-POINT VW PIEZOMETER

In stock

Rated 0 out of 5

STRAIN GAUGE PIEZOMETER SGP-3400 SERIES

In stock

Rated 0 out of 5

The SGP-3400 Series of strain gauge piezometers are designed for monitoring soil pore pressure or changes in water level and are also suitable for dynamic monitoring such as pumping tests.

They are accurate, highly-reliable and suitable for use in the harsh environments often found within civil engineering including water wells, boreholes, dams, reservoirs, rivers, tanks or any other body of water.

DRIVE-IN PIEZOMETERS WP-3400 & SGP-3500 SERIES

In stock

Rated 0 out of 5

Drive-in piezometers, also referred to as push-in piezometers, are designed for installing in soft clays, organic or fine grained cohesionless soils typically with a SPT-N value less than 10. They are available with a CPT fitting or 1” BSP thread.

Depending on the depth and type of soil, they can either be pushed directly into the soil from ground level to the required depth or pushed into the base of a CPT test or drilled borehole.

PRESSURE TRANSDUCER VWT-9000 SERIES

In stock

Rated 0 out of 5

The Geosense® VWT-9000 Series of Pressure Transducers are designed to be connected directly into hydraulic or pneumatic pressure lines by means of a 1/4” BSPF thread. Other thread sizes are available on request.

They are typically used to monitor uplift pressures within dams and to enable manual standpipe piezometers to be upgraded into an automated data acquisition system.

IN-PLACE TILT METER MEMS

In stock

Rated 0 out of 5

STANDPIPE PIEZOMETER

In stock

Rated 0 out of 5

WATER LEVEL METER

In stock

Rated 0 out of 5

HUMIDITY & CORROSION (CorroDec®2G)

In stock

Rated 0 out of 5

The structural infrastructure must always meet requirements such as performance, stability and durability. These requirements will have a lasting effect on our mobility in the future. The corrosion risk and the corrosion activity of the reinforcing steel largely define these requirements and are determined by various impact and material parameters.

Reviews

There are no reviews yet.